SS on 12/18, Damper endswitch on 13/19 (made when damper is fully open), Damper command on relay 1 (damper open when relay goes high)

Here is the sequence:

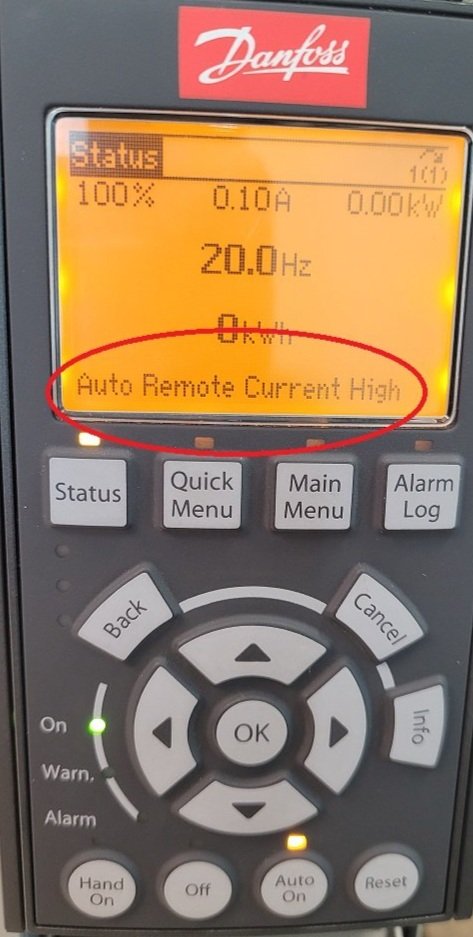

Start command received at 12/18 from EMCS

VFD goes to preset speed (example below is set for 15hz)

Relay 1 turns on to drive damper open when motor goes above 401rpm

When the damper endswitch is made to 13/19 then the VFD is under EMCS controls

When start signal is removed, motor will slow down. Damper will start closing when motor goes below 401rpm, the very slow ramp down time takes effect 180s in the example below.

Programming Steps:

0-50 lcp copy select [1] “all to lcp” **Copies existing parameters to keypad in case you need to restore them:

0-10 active setup, verify [1] “setup 1”

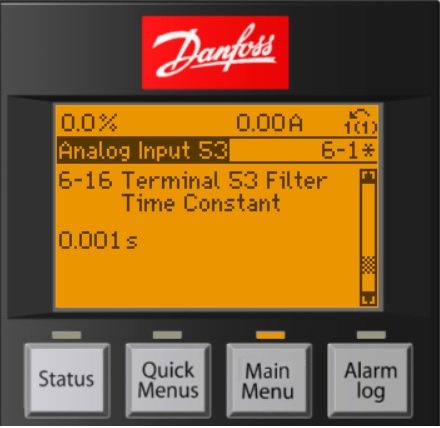

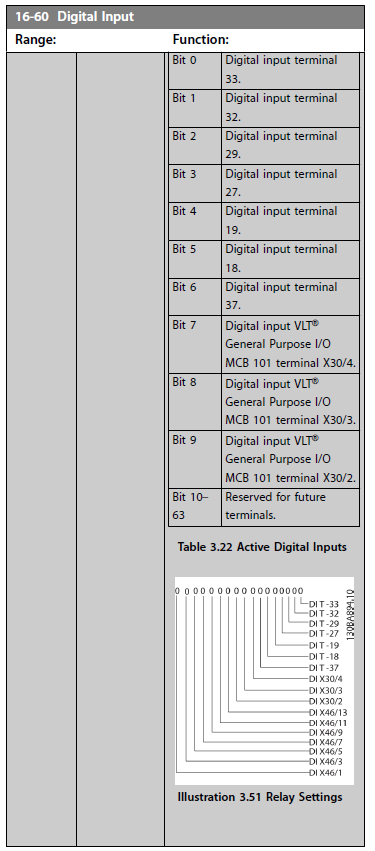

Set 5-11 term 19 to [23] “setup select bit 0” **allows the damper endswitch to change the setup, when its made the drive will go to setup 2

Set 4-53 warning speed high to 401rpm (set this to whatever speed works for you but must be below 4-12 min speed in Hz)

Set 5-40 function relay 1 set for [17] “above speed high” **activated the damper open command when speed goes above 401rpm

0-12 this setup linked to [2] “setup 2” **links the setups so you can switch during motor running

0-51 setup copy to [2] “copy to setup 2” copies these parameters to setup 2

While still in setup 1 (these settings are only for setup 1, not copied over to setup 2)

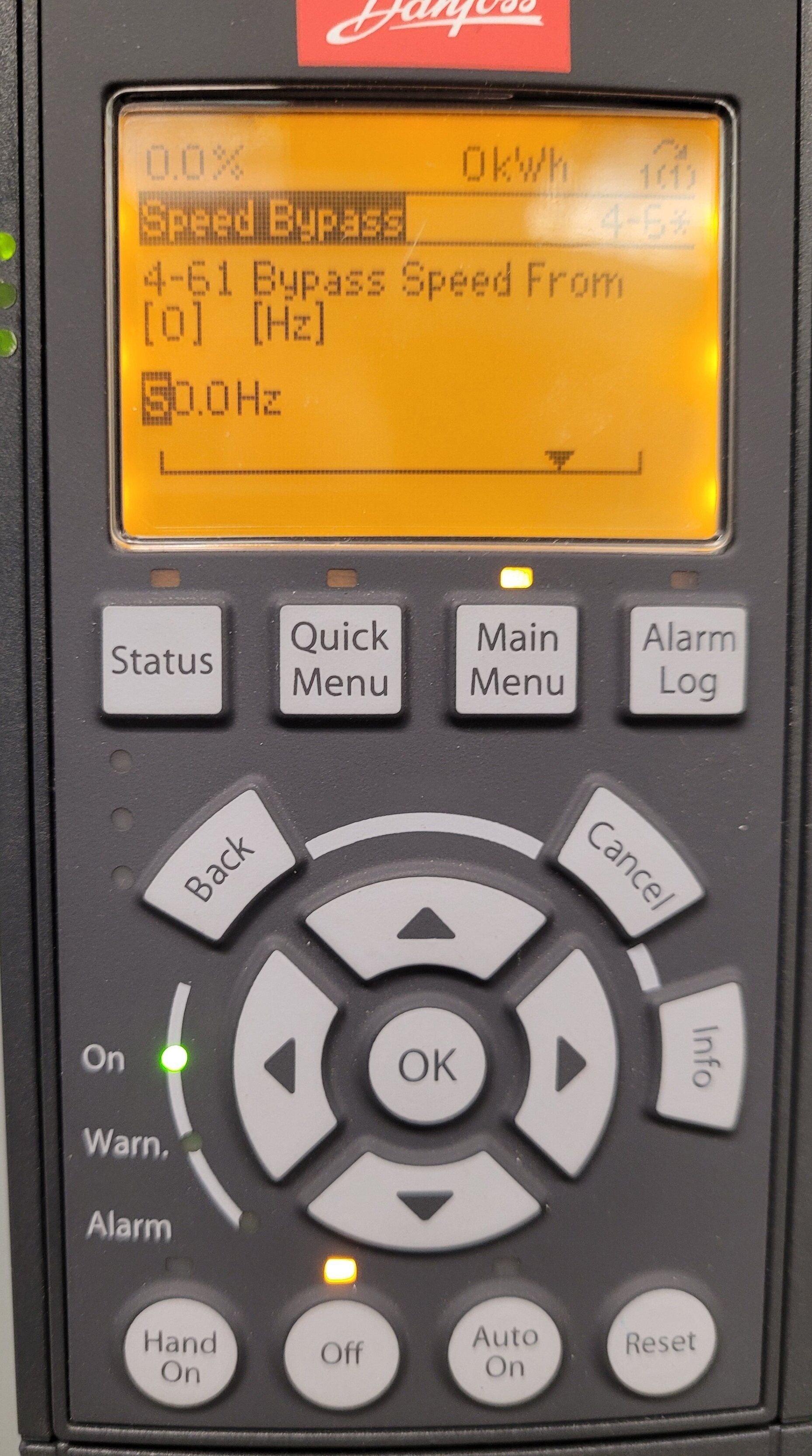

Set 3-02 minimum reference to 15Hz (or whatever low speed you want the VFD to run at when the damper is closed)

Set 3-03 maximum reference to 15Hz (or whatever low speed you want the VFD to run at when the damper is closed)

Set 3-42 ramp 1 ramp-down time for 180s (or some slow speed to ramp down while the damper is closing during motor stop, this will only affect the time from 401rpm to 0)

Change to setup 2

Set 0-10 active setup to [2] setup 2

Set 0-12 this setup linked to [1] “setup 1”

Set 0-10 active setup to [9] “multi-setup” **enables the damper endswitch to switch the setups

Cycle the VFD Power— this will reset the drive after all of the I/O changes that you made previously

Test the sequence to verify that it is working.

When all looks good then save the new parameters:

0-50 lcp copy select [1] “all to lcp”