Danfoss VFD Relay Delay Settings

/Hi- A customer has an isolation damper tied to a relay on the VFD, so that when the VFD is started the relay will open the damper. When the damper endswitch is made, the signal goes back to the VFD to allow it to start.

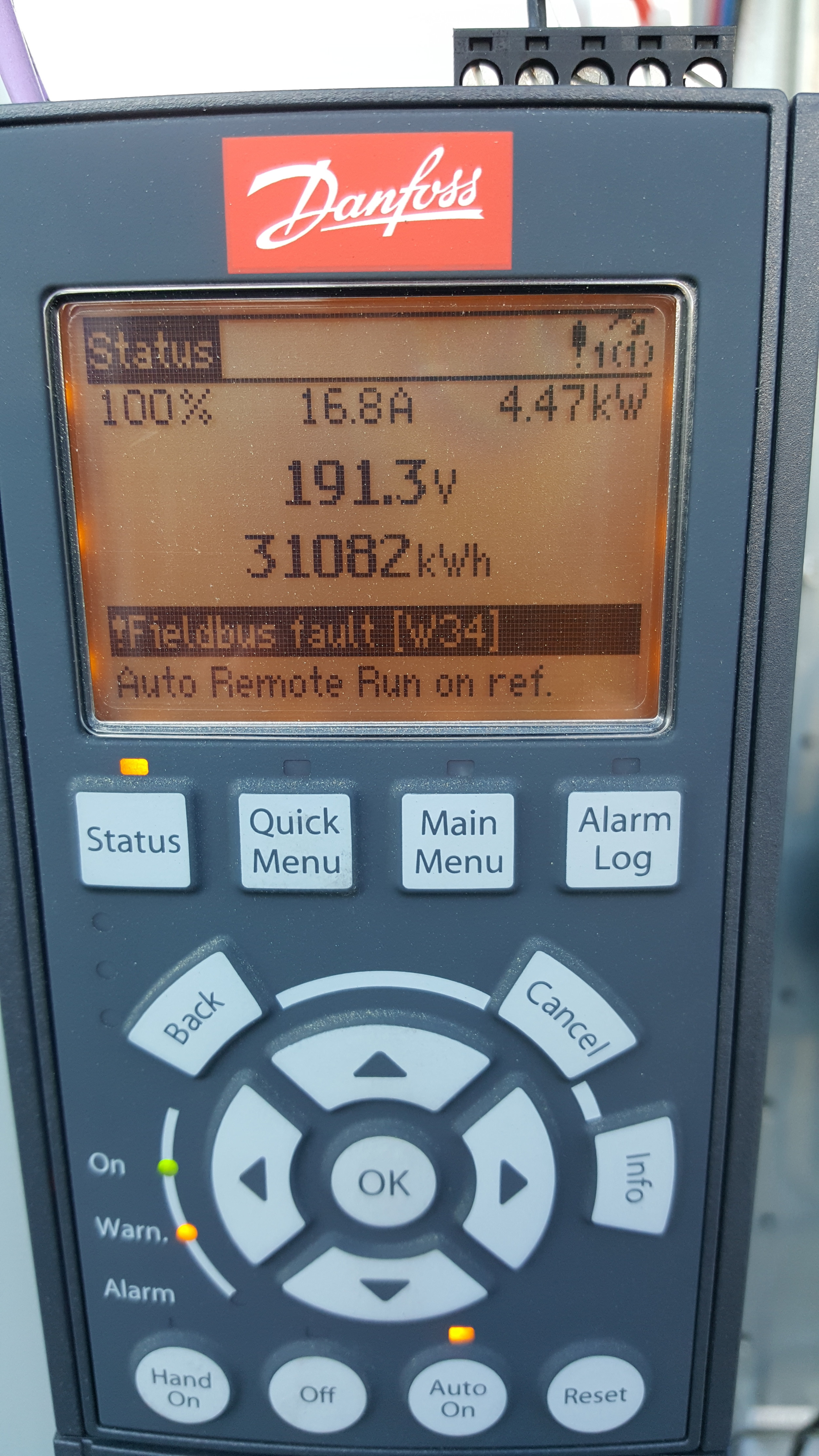

It looks like this:

Use the following points:

Set 5-40 relay 1 to [167] "Start Command Active". This works great for isolation dampers because the drive can open the damper with any start command or local hand operation.

Set 5-11 Terminal 19 (or any open input) to [52] "run permissive". If you tie a damper endswitch to that input, the motor will not start until there is a contact closure across the input.

Here is the secret sauce: When the VFD receives a "stop" command, you may not want the damper to close immediately while the fan is still winding down-- you might trip a pressure switch or otherwise damage equipment if the duct is closed while fan is still turning---

Set 5-42 Relay 1 Off Delay ---Set this to a long enough time to allow the motor to completely wind down before damper closure--- it should be at least as long as ramp down time in parameter 3-42-- probably add another 30s or so on top of that and test it.

As always call us if you have any questions!